Graphite Ingot Mould Mold Bar Jewelry Tool for Melting Furnace Casting Refining

- Description

- Additional information

- Reviews (0)

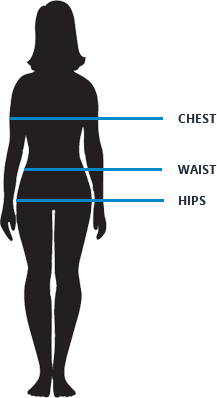

- Size Guide

Description

Unlock the potential of your melting furnace with the Graphite Ingot Mould, an essential tool designed to enhance your metal casting and refining processes. Whether you’re a professional jeweler, a metalworker, or an enthusiast exploring the world of metallurgy, this versatile mold is engineered to meet the demands of rapid temperature changes, strong acids and alkalis, and high-temperature applications. Let’s delve into the exceptional features and benefits of this indispensable jewelry tool, and discover why it’s a must-have for anyone involved in metal melting, casting, and refining.

Specification

- Name: Graphite crucible mold

- Model: SG-SMC

- Density:1.85g / cm * 3

- Resistance:13μΩ-m

- Anti-fold:55MP a

- Anti-stress:75MPa

- Hardness (Shore):35

- Granules: Average particle φ25μm

- Purity:99.95%

Exceptional Thermal Stability

One of the key attributes of the Graphite Ingot Mould is its exceptional thermal stability. It is engineered to withstand rapid transitions between hot and cold conditions, a critical requirement in metal casting and refining processes. This stability ensures that the mold remains intact and performs reliably even when exposed to extreme temperature fluctuations, allowing you to work with confidence and precision.

Corrosion Resistance and Durability

In the world of metallurgy and metal refining, exposure to strong acids and alkalis is not uncommon. The Graphite Ingot Mould is designed with this in mind, offering outstanding corrosion resistance. This resistance to chemical agents ensures that the mold maintains its structural integrity and longevity, even when used in harsh environments. Its impact-resistant properties further enhance its durability, making it a reliable choice for a wide range of applications.

Efficient Thermal Conductivity

Efficient thermal conductivity is crucial when working with molten metals. The Graphite Ingot Mould excels in this regard, ensuring that heat is evenly distributed throughout the mold. This even heat distribution minimizes the risk of uneven solidification and helps produce high-quality castings. Whether you’re crafting intricate jewelry pieces or refining metals for industrial applications, the mold’s efficient thermal conductivity is a valuable asset.

Exceptional Purity and Low Impurities

Metal refining demands a high degree of purity to achieve the desired results. The Graphite Ingot Mould boasts a glow content of less than 0.1%, ensuring that there are no other impurities introduced during the refining process. This exceptional level of purity translates to cleaner, higher-quality metals, which is essential for achieving precise results in your craftsmanship.

Extreme Heat Resistance

Working with molten metals often involves exposure to extreme temperatures. The Graphite Ingot Mould is designed to excel in these conditions, withstanding temperatures of up to 2000°C. This exceptional heat resistance ensures that the mold remains structurally sound and functional throughout the intense heat of metal refining, casting, and melting processes.

Longevity and Reusability

Durability and longevity are paramount when investing in jewelry tools and equipment. The Graphite Ingot Mould is built to last, with the capability to be used up to 20,000 times. Its extended lifespan translates to significant cost savings over time, as you won’t need to frequently replace the mold. This reusability makes it a practical and cost-effective choice for professionals and enthusiasts alike.

In conclusion, the Graphite Ingot Mould is an indispensable tool for anyone involved in metal melting, casting, and refining. Its exceptional thermal stability, resistance to strong acids and alkalis, efficient thermal conductivity, high purity, extreme heat resistance, and long lifespan make it an invaluable asset in the world of metallurgy and jewelry making. Whether you’re crafting intricate jewelry pieces or refining metals for industrial applications, this mold delivers the performance and reliability you need to achieve outstanding results. Elevate your metalworking capabilities and embark on a journey of limitless creative possibilities with the Graphite Ingot Mould.

Additional information

| capacity(ml) | 6ml, 10ml, 35ml, 60ml, 170ml, 250ml, 500ml, 150ml, 113ml |

|---|---|

| Brand | TOAUTO |

| Type | Molds |

| Suitable For | Jewelry Making |

Be the first to review “Graphite Ingot Mould Mold Bar Jewelry Tool for Melting Furnace Casting Refining” Cancel reply

| size | chest(in.) | waist(in.) | hips(in.) |

|---|---|---|---|

| XS | 34-36 | 27-29 | 34.5-36.5 |

| S | 36-38 | 29-31 | 36.5-38.5 |

| M | 38-40 | 31-33 | 38.5-40.5 |

| L | 40-42 | 33-36 | 40.5-43.5 |

| XL | 42-45 | 36-40 | 43.5-47.5 |

| XXL | 45-48 | 40-44 | 47.5-51.5 |

Reviews

There are no reviews yet.